3D Printing

At Monolith Performance, we specialise in carbon fibre reinforced 3D printing for applications where strength, thermal endurance and durability are mandatory. From one-off prototypes to low-volume production, our parts meet the tight tolerances and surface finish demands of motorsport and industrial users.

Key Benefits

-

Lightweight and durable mechanical components, resistant to temperatures up to 200 °C.

-

High-accuracy prototypes delivered in 2–4 working days. Short production runs completed within 5–10 days.

-

Improved surface quality and reduced layer lines; smoother finishes achievable on select machines, with primer-ready options available.

Our 3D Printing Process

Instant Quotation & Design Review

• Upload your CAD or STL files and receive an online quote within 1 business day.

• Our engineers review wall thicknesses, overhangs and assembly fits to ensure manufacturability.

1

Instant Quotation & Design Review

2

Material & Machine Selection

3

Build & Monitor

4

Post Processing & Quality Inspection

Typical Industries & Applications

Motorsport:

Mounting brackets, aerodynamic fins, intake manifolds

Automotive:

Custom fixtures, dash panels, tooling

Industrial:

End-use housing, pump components, handles

-

Up to 325× 32'0 × 325 mm (x, y, z) on our largest printer.

-

Yes — that’s the fun of 3D printing! Our machines allow us to batch as many parts as fit on the print bed in a single run.

-

We print in a wide range of engineering-grade polymers—including PLA, PETG-HF, ASA and PC—as well as carbon-fibre-reinforced composites (PLA-CF, PETG-CF, PA6-CF, PAHT-CF). Each material is selected for optimal strength, thermal endurance and chemical resistance.

Please visit our filament guide for more information.

-

Standard tolerances are ±0.2 mm. Layer resolution goes as fine as 50 µm, delivering smooth surfaces and precise detail for both prototypes and end-use parts.

-

Rapid prototypes: 1-2 working days from file upload to dispatch

Short production runs (10–50 pcs): 5–10 working days

Rush jobs and larger batches can often be accommodated—just let us know your deadline.

-

Absolutely. We accept most common formats (STL, OBJ, STEP, IGES). Simply upload your file via our online quote form and we’ll check manufacturability before confirming your order.

-

Pricing is based primarily on material, volume and machine time. Simple parts below 50 cm³ often qualify for fixed-rate quotes (from £25). After you upload your model, you’ll receive a detailed breakdown—no hidden fees

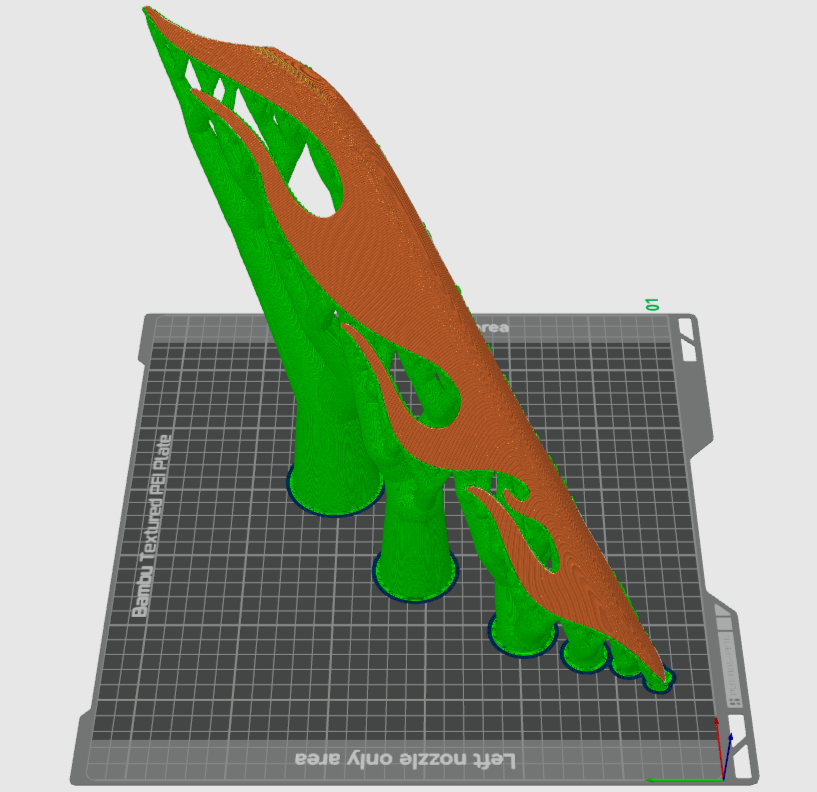

Timelapse of a high-strength wheel hub being 3D printed with carbon fibre-reinforced filament using a Bambu Lab printer. Engineered for motorsport and automotive applications in the UK