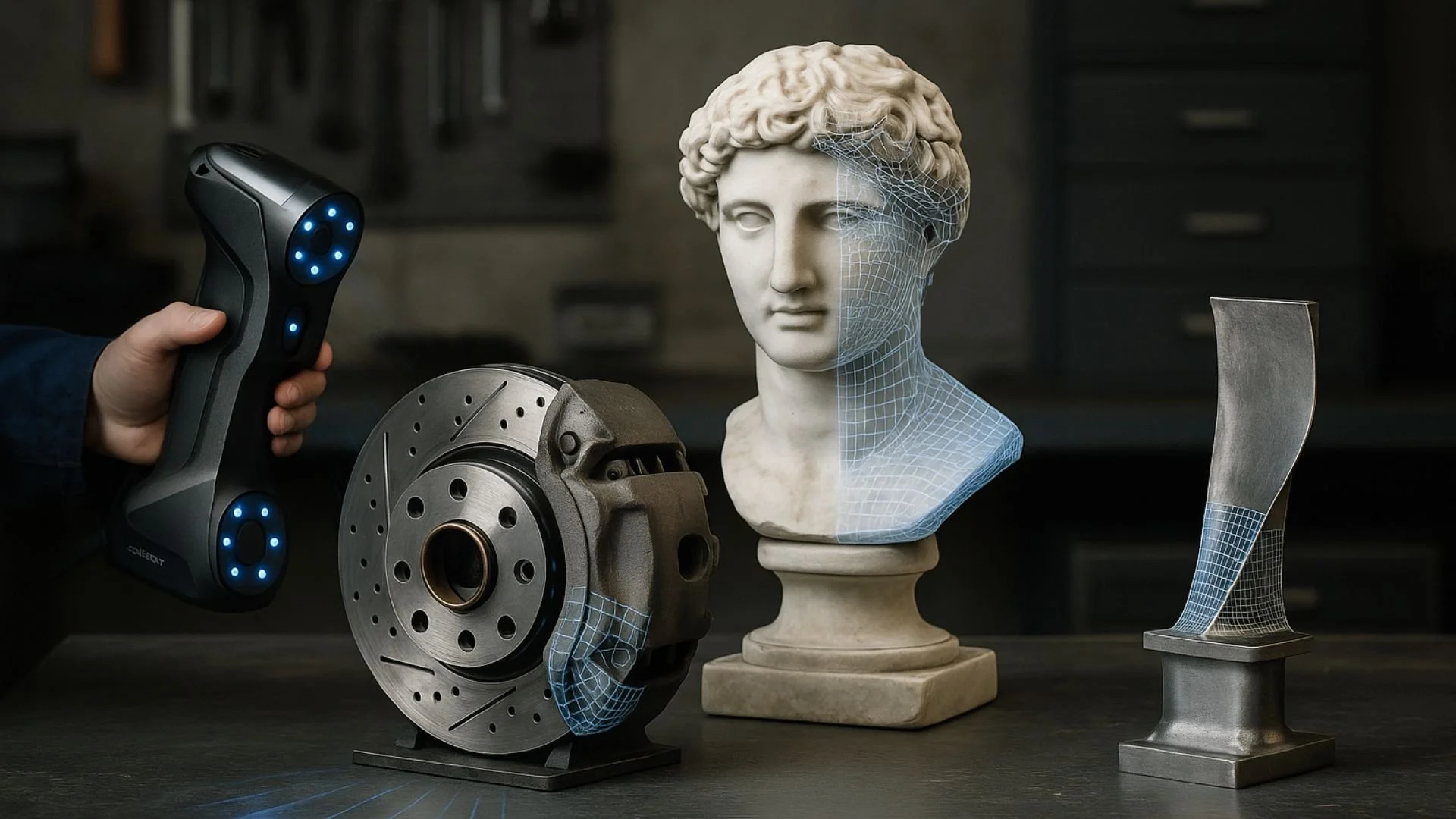

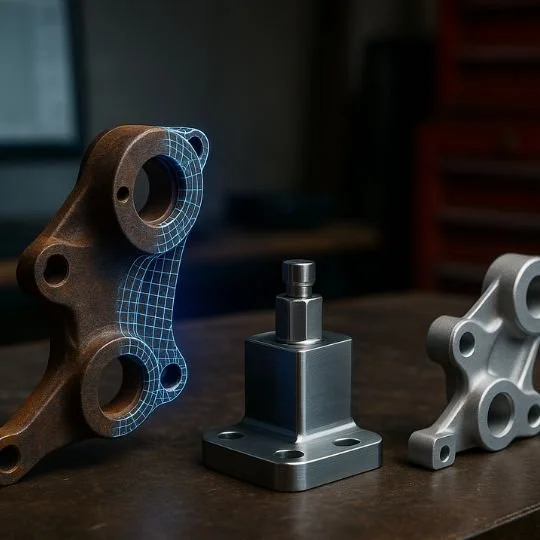

3D Scanning Services

At Monolith Performance, we offer high-precision 3D scanning to capture complex shapes with ease. Our contact-free system handles both small details and large parts, with typical accuracy between ±0.03–0.05 mm.

It adapts to different surfaces, sizes, and finishes — perfect for reverse engineering, quality control, or digital replication.

BMW E46 Front Grill

-

Simple parts (< 1 m² surface) are scanned, processed and delivered within 1–2 weeks. Large or highly detailed assemblies typically require 3–4 weeks.

-

We deliver raw point clouds (.PLY), meshes (.STL, .OBJ) and parametric CAD models (STEP, IGES)

-

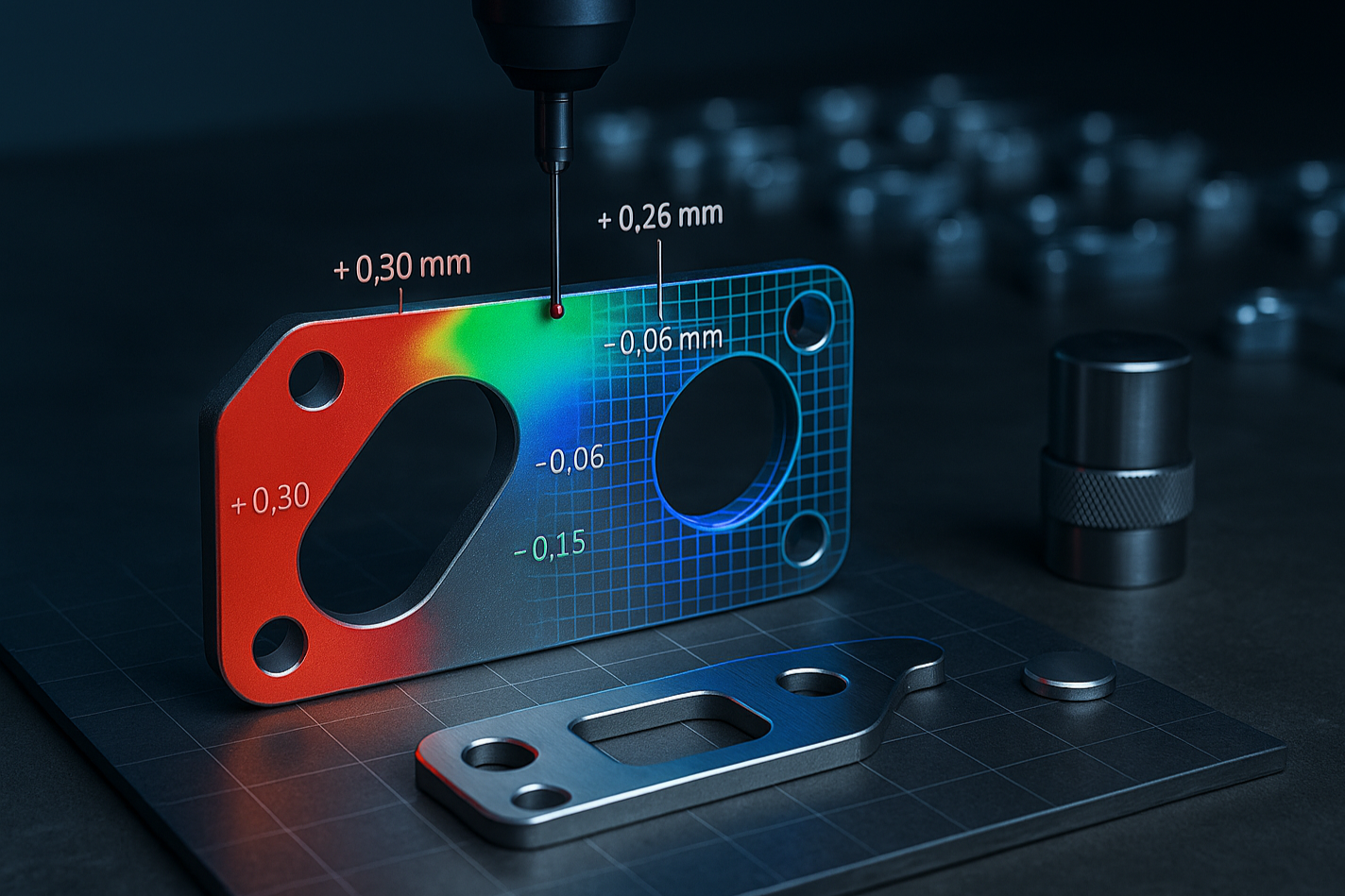

We routinely achieve ±0.03–0.05 mm accuracy, with point spacing as fine as 0.02 mm for detailed components.

-

Yes — our portable structured-light and photogrammetry systems can scan large objects up to 3 metres, including in-situ equipment and fixed installations.

-

Yes—although these materials can pose challenges, we use temporary matt-spray coatings or special scanning modes to capture accurate data on shiny, glass or clear plastics without compromising final part quality.

-

All scan data is transferred via secure, encrypted links and stored on GDPR-compliant servers. We’re happy to sign NDAs or comply with your corporate security policies to keep your IP safe.

Our 3D Scanning Workflow

1.

Object Preparation

2.

Surface Scanning

3.

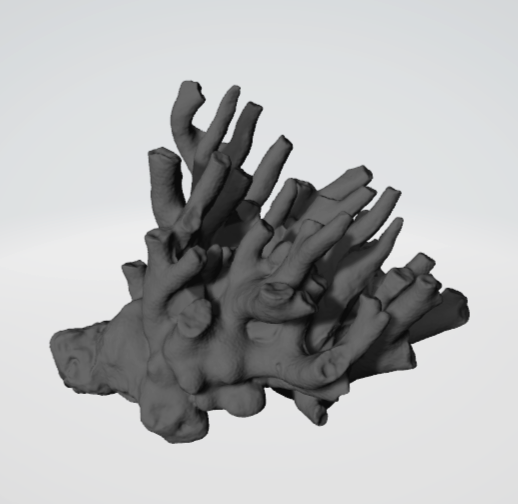

Capturing the Digital Mesh

4.

Refining and Cleaning the Geometry

5

Usable CAD File

Deliverables & File Formats

Raw Point Cloud: .PLY

Optimised Mesh: .STL, .OBJ

Parametric CAD: STEP, IGES

Inspection Report (optional): Comparison to original CAD or measured specifications

All files are quality-checked and delivered via a secure download link.

Typical Industries & Applications

Heritage & Conservation:

Digital archiving of sculptures, architectural elements

Quality Control:

Inspecting initial prototypes, checking part tolerances, and validating batch samples.

Reverse Engineering: Recreating legacy parts, designing custom tooling, and producing replacement components.

Automotive & Motorsport:

Mounting brackets, aerodynamic ducts, supports, and prototype test parts.