Reverse Engineering Services

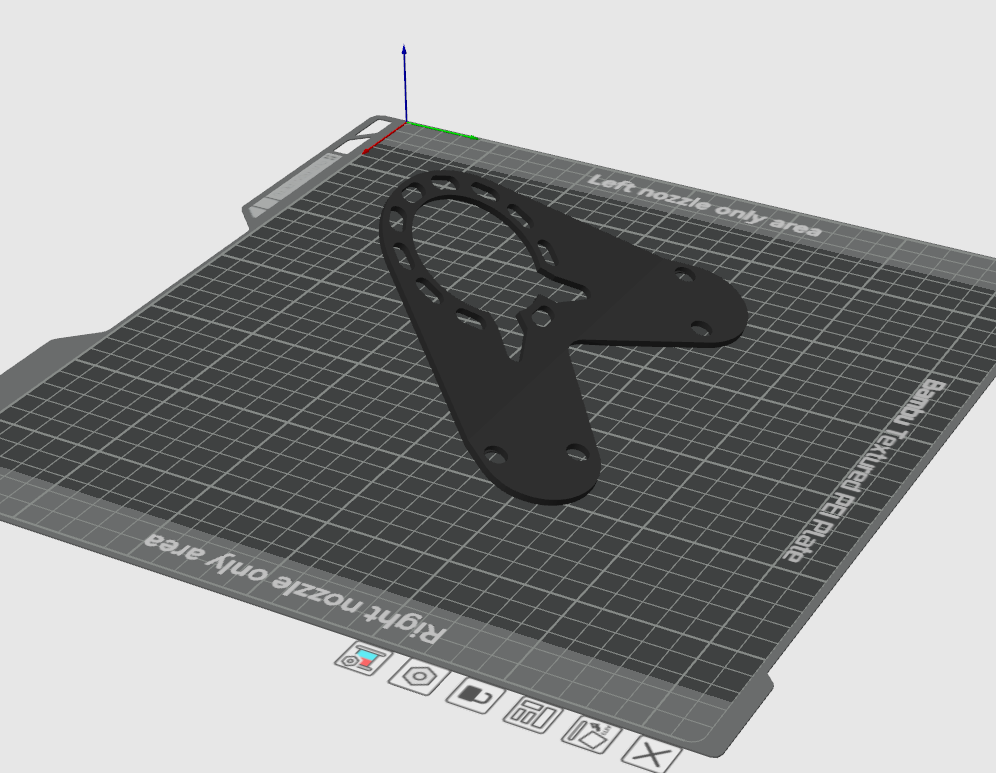

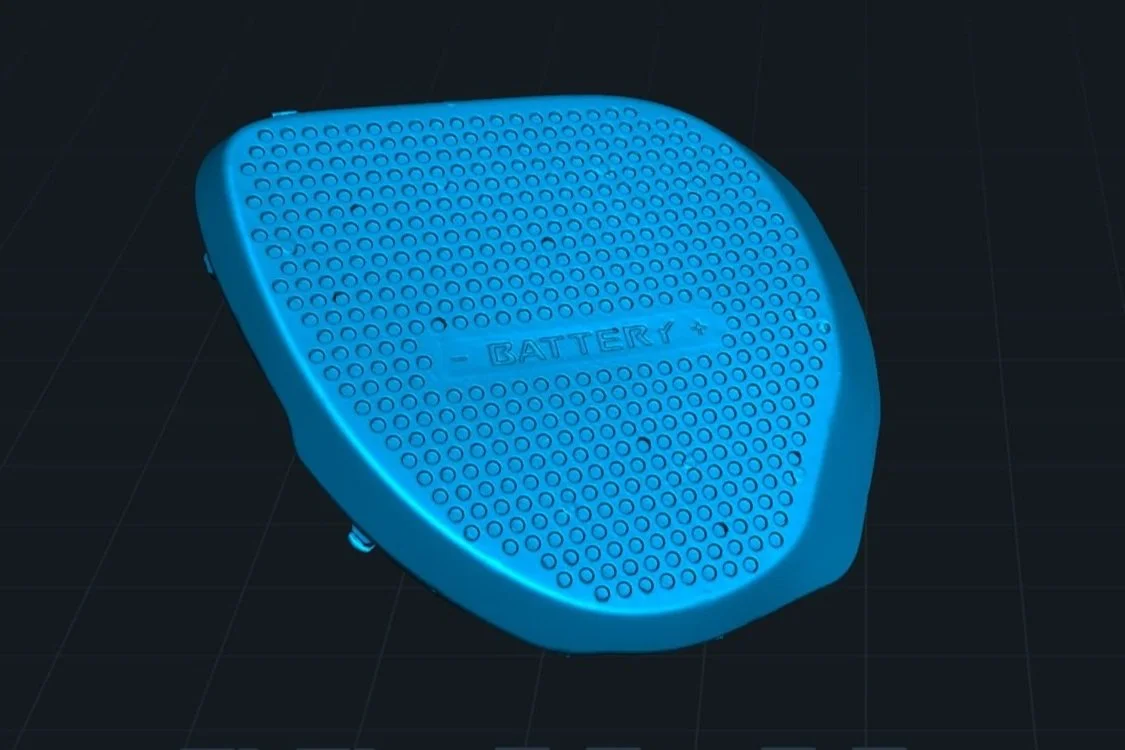

We transform your legacy or undocumented parts into fully editable CAD models using high-precision scan data and expert surface modelling workflows. Ideal for obsolete components, design improvements and technical documentation.

Quick Quotation & Design Review

• Upload your CAD or STL files and receive an online quote within 1 business day.

• Our engineers review wall thicknesses, overhangs and assembly fits to ensure manufacturability.

Our Reverse Engineering Process

1

High-Precision 3D Scan

2

Point-Cloud & Mesh Optimisation

3

Surface-and Solid-Model CAD Recreation

4

Dimensional Verification

Deliverables & File Formats

Optimised Mesh: .STL, .OBJ

Editable CAD Model: STEP, IGES

Inspection Report: PDF with colour-map overlays and dimensional tables

2D Drawings (optional): PDF, DWG

All files are delivered via secure download link within agreed turnaround times.

Typical Industries & Use Cases

Automotive & Motorsport: Prototype components, tooling jigs, crash parts

Heritage & Conservation: Precision-faithful CAD for restoration projects

Industrial Machinery: Spare parts replacement, custom machine components

Medical Devices:

Reverse engineering of organic surfaces/structures

Whether you need to revive an out of production component, optimise your tooling, or create custom spares on demand, Monolith Performance’s reverse engineering service leverages state of the art 3D scanning and additive manufacturing to bring your designs back to life, better, faster, and stronger.

-

Reverse engineering is the process of turning a physical part into a fully editable CAD model by capturing its geometry (via 3D scan), cleaning and reconstructing the mesh. It’s ideal for undocumented or obsolete components where no original CAD data exists.

-

Legacy Parts Reproduction

Many critical components, especially those used in aerospace, automotive, or industrial machinery, are no longer in production. Reverse engineering lets you recreate these parts exactly, restoring functionality without needing original drawings.Tooling & Fixture Design

By capturing an existing part’s exact geometry, you can design jigs, fixtures, or molds that fit perfectly, speeding up setup times and ensuring repeatable accuracy.Spare-Parts Manufacture

Small batches of specialized parts (e.g., custom fasteners, machined brackets) become cost-effective when you can scan and print or machine them yourself.

-

3D Scanning: We capture your part’s surface with ±0.03-0.05 mm accuracy.

Mesh Processing: Raw point-cloud data is cleaned, holes are filled and a watertight mesh (.STL/.OBJ) is generated.

CAD Recreation: Expert modelers rebuild surfaces as parametric solids in STEP, IGES.

-

We handle everything from small precision parts (<50 mm) to large assemblies (several metres). Portable scanners let us perform in-situ capture of fixed equipment, while our desktop systems excel at fine-detail components.

-

Editable CAD models: STEP, IGES

Optimised mesh: STL, OBJ

Inspection reports: PDF with deviation maps and dimensional call-outs

2D drawings: DWG or PDF (optional)

All outputs are delivered via secure download link.

-

Simple parts: 7–10 working days

Complex or large assemblies: 15–20 working days

Rush services can often be accommodated; just let us know your deadline.

-

Yes. Our CAD recreation process can incorporate design improvements, wall-thickness adjustments, weight reduction features or added mounting points, and we document any changes with revision history for full traceability.

-

Absolutely. We understand the sensitivity of proprietary designs. Monolith Performance will sign your NDA or work under our standard confidentiality agreement to keep your IP fully protected.